Enhance Top Quality Guarantee and Conformity Criteria With Professional Welding Examination Solutions

In the world of manufacturing and construction, the value of adhering to strict quality guarantee and conformity standards can not be overemphasized. Expert welding assessment solutions play a critical duty in ensuring that these requirements are consulted with precision and precision. By getting the know-how of experienced welding examiners, companies can not just guarantee compliance with market policies yet likewise boost their quality assurance measures. The advantages of such precise examination services prolong past simple conformity, bring about improved product safety and performance. As we browse through the intricacies of welding inspection solutions, it comes to be noticeable that the competence and focus to detail supplied by experts in this field are crucial for keeping the greatest requirements of quality and conformity.

Importance of Welding Evaluation Solutions

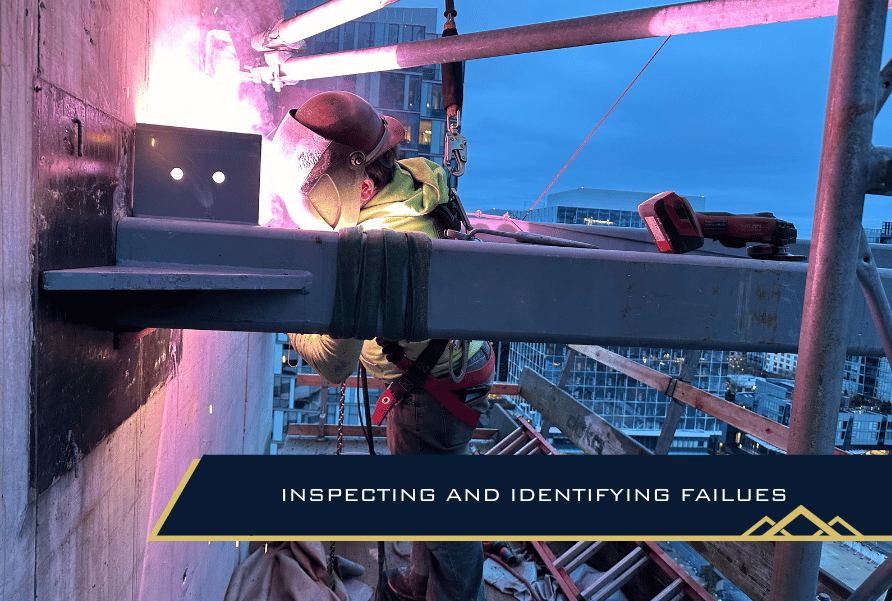

Making sure the top quality and safety and security of bonded structures, welding evaluation services play a vital duty in numerous sectors. By carrying out extensive evaluations, these services aid in identifying any kind of welding problems, gaps, or flaws that could compromise the honesty of the structure. Welding examinations are essential for keeping conformity with industry requirements and laws, along with making certain the longevity and integrity of the bonded elements.

One secret significance of welding assessment solutions is the avoidance of prospective hazards and crashes. By identifying welding problems early, these services assist in mitigating dangers connected with structural failings, leaks, or other operational issues. In addition, welding inspections aid in maximizing the general performance and performance of welded structures, adding to cost financial savings and enhanced performance for services.

Benefits of Professional Assessment

One of the main advantages of expert examination solutions is the early discovery of welding problems, which assists protect against expensive rework or repairs down the line. Expert assessments aid promote conformity with pertinent codes and requirements, securing the online reputation of the company and fostering a society of excellence in welding methods. Overall, investing in expert welding inspection solutions produces lasting advantages by advertising efficiency, adherence, and safety and security to sector finest practices.

Conformity With Industry Requirements

One of the basic pillars of keeping the architectural integrity and high quality assurance in welding processes is lining up with industry standards. These requirements are established to manage the welding procedure, products used, security methods, and overall high quality control measures.

Additionally, conformity with sector standards not only makes certain the security and reliability of bonded structures but likewise boosts integrity and trust with consumers, regulative bodies, and other stakeholders. It signifies a devotion to excellence and professionalism and reliability in welding techniques, which can establish a firm apart in an affordable market. On the whole, straightening with sector requirements is crucial for promoting quality control, attaining regulatory conformity, and cultivating a credibility for quality in welding processes.

Enhancing High Quality Control Measures

Improving weld top quality control measures is critical for making certain the reliability and security of bonded structures. By improving quality assurance measures, business can minimize problems, decrease rework, and ultimately deliver superior products to their consumers. One efficient way to improve quality control procedures is to carry out detailed assessment protocols throughout the welding process. This consists of evaluating resources prior to welding, keeping track of the welding criteria during the process, and carrying out post-weld inspections to detect any type of flaws or imperfections.

Moreover, spending in innovative welding innovations and equipment can also significantly enhance quality assurance measures. Automated welding systems, for example, can provide even more exact and constant welds compared to hand-operated welding procedures. Additionally, giving regular training and accreditation programs for welders can make sure that they are current with the most recent requirements and strategies, even more improving the top quality of welds.

Improving Product Security and Performance

Enhancing product security and performance is necessary in ensuring the integrity and durability of welded frameworks. By investing in professional welding assessment services, manufacturers can considerably enhance the total quality of their items (Welding Inspection Racine). Through comprehensive examinations and adherence to compliance criteria, prospective flaws or weak points in the welding procedure can be identified and rectified quickly, eventually improving the safety and efficiency of the end product

Product security is paramount in markets where bonded structures are extensively utilized, such as construction, automotive, and aerospace. Any type of concession in the welding stability site link can result in disastrous effects, including structural failures and security threats. Prioritizing welding evaluation services not just makes sure conformity with industry policies however also infuses self-confidence in the item's integrity and efficiency.

Furthermore, by proactively dealing with any welding problems or disparities, makers can enhance the total top quality of their items, causing increased client fulfillment find out here and count on. Improved item safety and efficiency also contribute to long-term expense savings by decreasing the possibility of rework, repairs, or item failures. In verdict, purchasing specialist welding assessment solutions is an aggressive strategy to assuring the security, dependability, and performance of bonded structures.

Verdict

Finally, professional welding inspection services play a vital duty in ensuring compliance with market standards, enhancing quality special info control actions, and boosting product security and performance. With the help of these solutions, companies can preserve top quality assurance degrees and meet governing demands, inevitably bring about better products and boosted customer fulfillment.

Guaranteeing the high quality and security of welded structures, welding examination solutions play a vital role in different industries.In addition, welding inspection services provide a level of assurance to stakeholders, demonstrating a dedication to quality and safety criteria. In verdict, the relevance of welding examination services can not be overemphasized, as they are vital for upholding quality, safety and security, and conformity in welding processes across industries.

Automated welding systems, for instance, can provide even more constant and precise welds contrasted to manual welding procedures.

Comments on “How Welding Inspection Racine Makes Sure Safety And Security and Conformity”